In the ever-evolving landscape of warehouse safety, traditional flooring solutions are increasingly falling short, especially when it comes to preventing slip and fall accidents in wet conditions.

As Health and Safety professionals, it's crucial to stay ahead of the curve and consider innovative approaches to this persistent challenge.

The Hidden Costs of Conventional Flooring

Traditional warehouse flooring often becomes a liability when exposed to moisture. It shows its weaknesses in:

- Increased accident risk

- Productivity losses

- Potential legal implications

- Higher insurance premiums

These issues stem from conventional flooring's inability to maintain grip in wet conditions, a common occurrence in many industrial settings.

The Science of Slip Resistance

Understanding slip resistance is key to addressing this issue effectively. Let’s start with two terms you can reference when shopping for the best flooring solutions:

- Coefficient of Friction (COF): Measures the grip between footwear and flooring

- Pendulum Test Value (PTV): A standardised measure of slip resistance

Ideal flooring should maintain high COF and PTV scores even when wet, a feat many traditional solutions fail to achieve.

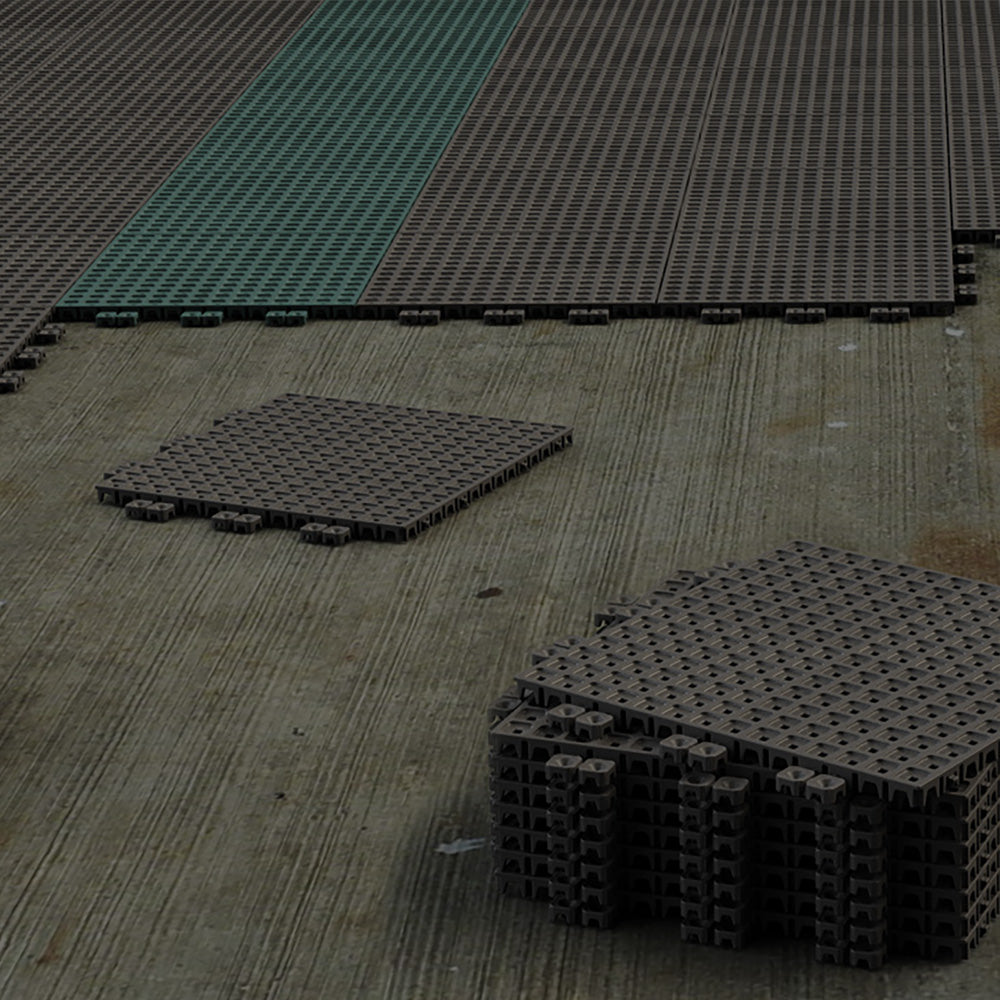

Revolutionary Modular Flooring: A Forward-Thinking Solution

Modern modular flooring systems are transforming warehouse safety. Here are four key benefits that Health and Safety Executives from some of the country’s largest businesses have shared with us (you’ve likely received a delivery from one of them recently):

1. Consistent Slip Resistance

Advanced modular tiles maintain grip levels in both dry and wet conditions, often achieving low slip risk classifications even when wet.

2. Rapid Water Dispersal

Innovative designs incorporate drainage features, quickly channelling water away from the surface and reducing standing water risks.

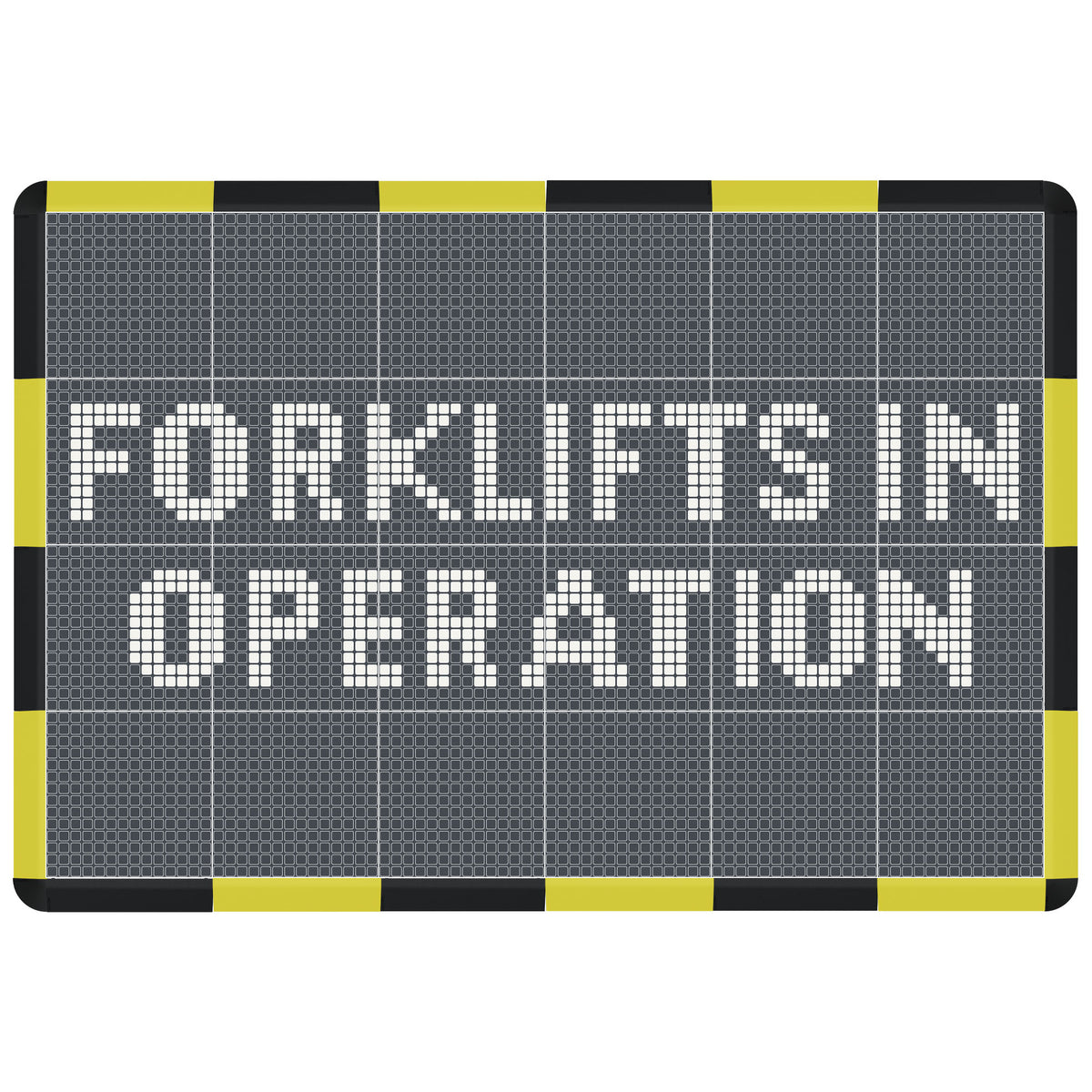

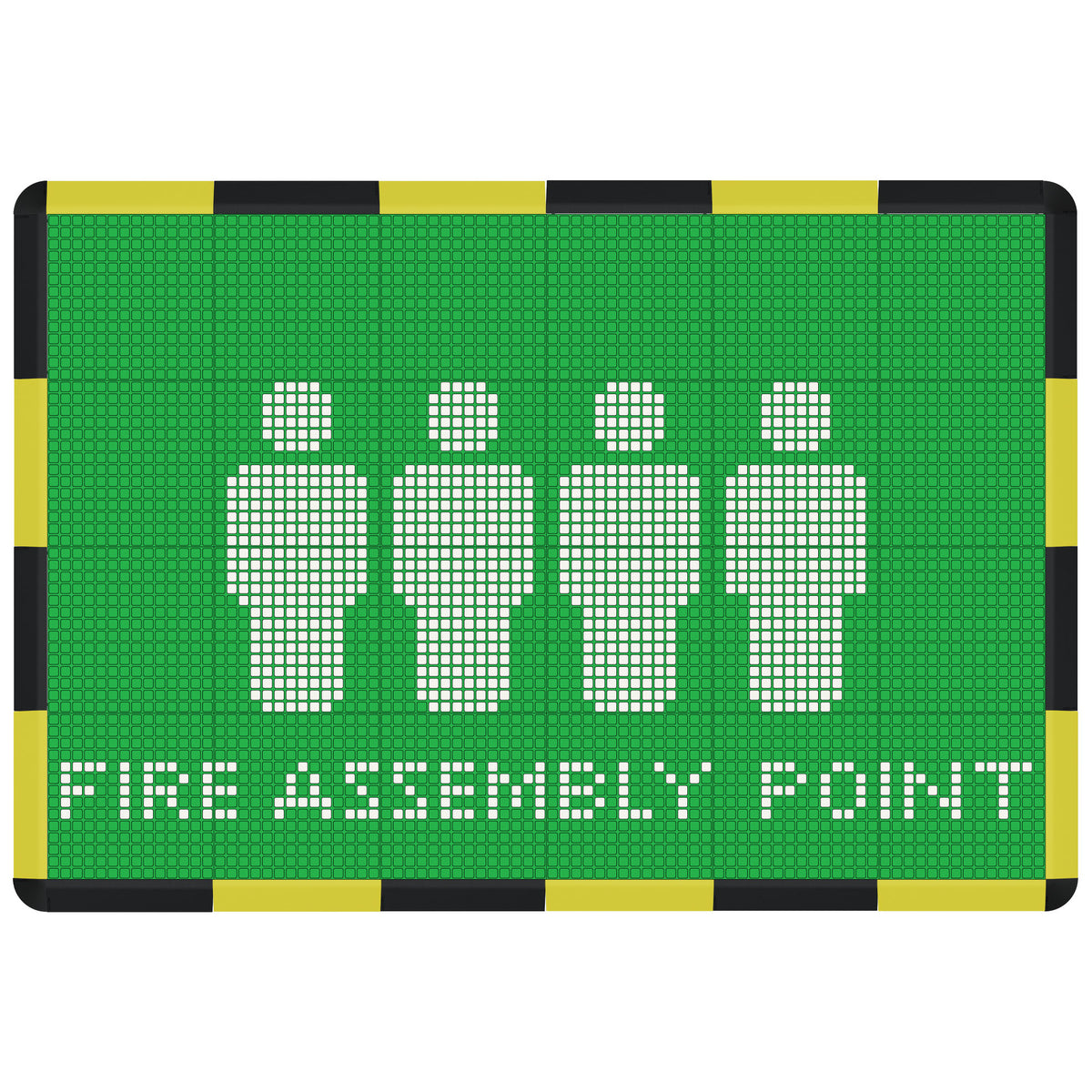

3. Customisable Safety Features

Modular systems allow for the integration of visual safety cues, creating a comprehensive safety environment beyond just slip prevention. Communication really is key!

4. Adaptability and Easy Maintenance

Unlike permanent flooring, modular solutions can be easily replaced or reconfigured as needs change, ensuring ongoing safety and efficiency.

Implementing a Modern Flooring Strategy

To leverage these advancements follow these 6 steps:

- Assess current flooring performance, particularly in wet conditions.

- Identify high-risk areas for slip hazards.

- Research modular flooring options that meet or exceed safety standards.

- Consider a phased implementation approach.

- Train staff on new flooring features and update safety protocols.

- Monitor and document the impact on slip-related incidents.

Beyond Slip Prevention: Holistic Safety Benefits

Advanced modular flooring contributes to overall workplace safety and efficiency:

- Reduced fatigue through ergonomic design

- Improved visibility with integrated safety markings

- Enhanced cleanliness due to easy-to-clean surfaces

- Potential noise reduction properties

The Future of Warehouse Flooring Safety

As technology advances, we can expect further innovations in modular flooring:

- Smart sensors for real-time slip risk assessment

- Self-cleaning surfaces to maintain grip levels

- Integration with wearable safety technology

The landscape of warehouse safety is changing, and flooring plays a crucial role in this evolution. By embracing innovative modular flooring solutions, Health and Safety professionals can proactively address slip hazards, even in wet conditions. This forward-thinking approach not only enhances safety but also contributes to overall operational efficiency and worker well-being.

As we move towards smarter, safer workplaces, it's time to reconsider traditional flooring approaches and explore the possibilities offered by modern modular solutions. The future of warehouse safety is here – and it starts from the ground up.